STUDY OF CROSSOVER EFFECT IN COMPRESSIVE STRENGTH OF CEMENT-BASED MATERIALS CONTAINING SUPPLEMENTARY CEMENTITIOUS MATERIALS

DOI:

https://doi.org/10.71146/kjmr604Keywords:

Compressive Strength, Cement,, Cementitious Materials, Crossover Effect, Accelerated CuringAbstract

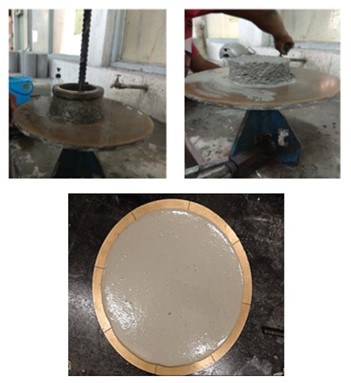

In cement-based materials (CBMs), cement hydration process and resulting compressive strength depend on their mix composition, curing temperature, curing methods and curing duration. The strength-gaining rate and hardening process of CBMs under normal curing regimes are slow. Therefore, accelerated curing techniques are applied for gaining high early-age strength. CBMs subjected to an initial high curing temperature undergoes accelerated hydration resulting in non-uniform scattering of the hydration products. It creates a great porosity and reduction in compressive strength at later ages. This phenomenon is called crossover effect (COE). Currently, the use of supplementary cementitious materials (SCMs) is becoming mandatory due to economic, environmental and sustainable issues. In this research, compressive strengths of mortar samples having 30% and 50% of fly ash (F-ASH), ballast furnace slag (GSP), ground and treated palm oil fuel ashes (GPA and TPA) in replacement of conventional Portland cement (CPC) were determined under accelerated curing conditions of HWC and HAC in short and long terms. The data obtained demonstrated that COE was observed in CPC control and blended mixes from 56 to 150 days; however, it was less than 10% for all of these mixes.

Downloads

Downloads

Published

Issue

Section

Categories

License

Copyright (c) 2025 Sumra Yousaf, Sunera Imtiaz, Shimza Jamil, Aalia Faiz, Muhammad Hamza Bhatti (Author)

This work is licensed under a Creative Commons Attribution 4.0 International License.