CO-PYROLYSIS OF RICE HUSK AND DATE PALM SEEDS: INFLUENCE OF TEMPERATURE AND BLENDING RATIO ON PRODUCT YIELDS AND GAS EVOLUTION

DOI:

https://doi.org/10.71146/kjmr571Keywords:

Co-pyrolysis, Rice husk, Date palm seed, Products distribution, Synergistic effect, gas evolutionAbstract

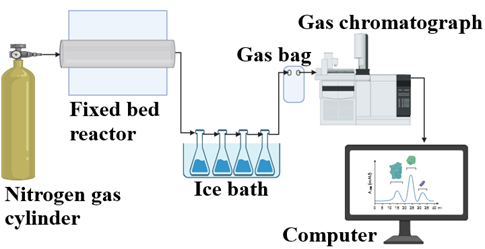

In this study, the effects of blending ratio and temperature on product distribution during co-pyrolysis of rice husk (RH) and date palm seed (DS) were investigated. The pyrolysis products were generated using fixed bed reactor and gaseous products were analyzed using gas chromatography. The solid yields consistently decreased over the entire temperature range from 300 to 600 °C for all biomass feedstocks. The liquid yield for 100%RH was found to increase to 35.35% from 300 to 500 °C, with the maximum yield observed at 500 °C. At higher temperatures, the liquid yield decreased. For 100%DS, the liquid yield increased up to 400 °C, reaching a maximum of 48.59% at this temperature, and then decreased at higher temperatures. An increasing proportion of DS led to a decrease in char and gas yield, thereby increasing liquid yield. Among the blends, the maximum liquid yield was obtained with a 75% proportion of DS in the blend. The solid yield exhibited a negative deviation, while the liquid yield showed a positive deviation across most temperatures and blending ratios. Thus, the co-pyrolysis of RH and DS reduced the char yield and promoted the formation of bio- production. CO2 yields from all blends were maximum in the temperature range of 400-500 °C. The 25%DS+75%RH blend exhibited higher CO yield than the 100%DS sample across all temperature ranges. The 50%DS+50%RH and 75%DS+25%RH blends showed higher CO yields than the individual samples during the isothermal stage. All blends produced higher H2 yields than the individual samples at 500-600 °C, with the 25%DS+75%RH and 75%DS+25%RH blends exceeding the individual samples during the isothermal stage. The 25%DS+75%RH and 75%DS+25%RH blends also had higher CH4 yields than individual samples in the 400-500 °C range, and the 75%DS+25%RH blend showed the highest CH4 yield compared to individual samples during the isothermal stage.

Downloads

Downloads

Published

Issue

Section

License

Copyright (c) 2025 Tarique Ahmed Memon, Faheem Ahmed, Athar Ali Khan Gorar, Asmatullah, Azhar Hussain Shah (Author)

This work is licensed under a Creative Commons Attribution 4.0 International License.